Your Guide to Premium denim Edge-to-Edge Material

Have you ever wondered why some pants seem like they’re designed for longevity a lifetime? Everything revolves around the components and skill. Consider the growing popularity of superior selvedge. It’s not merely ordinary material—it attests to superiority and tradition.

Today, a growing number of people are opting for these classic fabrics for their robustness and classic selvedge denim fabric appeal. Be it that you are a home sewing sewist or a denim lover, there’s a unique quality about working with high-quality cotton and thread. It isn’t solely concerned with creating pants; it’s about producing a legacy.

At Core Fabrics, we’ve assembled a selection of 14.25oz certified organic cotton and elastic options. These materials are tailor-made for a spectrum ranging from raw trousers to couture jacket patterns. Ready to explore the world of premium fabrics? Let us delve in.

Understanding Denim Selvedge Fabric?

What is it that makes particular trousers stand out with their signature, naturally edged edges? The key resides in the selvedge denim, a premium material known for its durability and old-school appeal. Differing from standard textiles, this fabric is crafted with traditional methods that have endured through ages.

The Definition of Selvedge Denim

Selvedge denim is produced using old-style shuttle looms, which generate slender widths of about 30-35 inches. They intertwine the textile in a way that creates self-finished seams, often highlighted by a characteristic red line. This process ensures the material is densely interlaced and highly durable.

Modern looms, alternatively, generate broader fabric but fall short of the equivalent of artistry. Minor flaws in selvedge, like misaligned seams or irregular surfaces, are accepted as features of its character. This ideology, termed “the beauty of imperfection”, honors the beauty of organic flaws.

How Selvedge Denim Is Made

The manufacturing of selvedge denim involves a exacting process. These looms interlace the horizontal threads in alternating directions, resulting in a thick and sturdy textile. This method contrasts with contemporary machines, which emphasize rapid output over craftsmanship.

Companies such as Karson Denim maintain time-honored Japanese methods from the 90s. They purposefully add flaws to maintain the true character of the material. Every item is evaluated on a four-point system, guaranteeing it fulfills the top criteria of superiority.

| Attribute | Selvedge Denim | Contemporary Denim |

|---|---|---|

| Width | 30-35 inches | 60+ inches |

| Construction Technique | Traditional Shuttle | Modern Loom |

| Surface | Non-uniform, Raw | Consistent |

| Strength | Exceptional | Standard |

“The allure of selvedge resides in its natural irregularities—every imperfection narrates a tale artistry and heritage.”

The Background of Selvedge Denim

Evolving from simple roots to worldwide renown, the story of these materials is vibrant and inspiring. Originally developed as hardwearing clothing in 17th-century France has become a mark of everlasting fashion and artistry.

Beginnings in Craftsmanship

The roots of this fabric reaches back to Nîmes, France, where it was referred to as “serge de Nîmes.” First intended for laborers, it was constructed with robust cotton and thread. Its durability ensured its popularity among laborers during the era of the Gold Rush.

In the 20th century, it had transformed into a cornerstone for trousers. The closure of the Cone Mills White Oak facility marked a turning point. This change enabled Japanese artisans to restore classic fabric-making practices.

Modern Developments in Denim

Following WWII, Japan embraced old-school American culture. Artisans repaired old looms to manufacture authentic reproductions. This devotion to quality ensured the continuance of selvedge as a unique product.

Today, breakthroughs from Italy and Turkey have launched sustainable combinations and stretch options. These modernizations have widened the attraction of this classic fabric. At Core Fabrics, we procure internationally, from Montréal to Asia, to deliver to you the finest excellence.

“The history of selvedge is a celebration of the enduring value of excellence and heritage.”

Why Choose Selvedge Denim?

Why does selvedge denim shine in the realm of superior fabrics? Its unique qualities and incomparable robustness render it popular among lovers and creatives alike. Be it that you are making pants or a structured jacket, this textile offers a mix of heritage and modern appeal.

Unique Qualities of Selvedge Fabric

Selvedge denim is celebrated for its tight weave, which boosts durability and color fading characteristics. Unlike standard materials, selvedge denim material is fashioned using classic shuttle looms, yielding a more compact and more durable product. In doing so, it secures that every item possesses a distinct surface and personality.

Notable attributes are:

- Coarse, stiff raw denim juxtaposes against laundered, relaxed stretch options.

- The sanforization process ensures predictable sizing, while untreated fabrics provide a unique shrinkage journey.

- Available weights span from 9.5oz Eco Finish to 14.25oz Organic, suited for different needs.

Robustness and Endurance

One of the standout features of selvedge denim is its long life. The tighter weave boosts robustness while enabling characteristic wear patterns over time. This makes it a treasured choice for those looking for classic garments.

Key points to consider:

- Fabrics weighing between 12oz and 14oz are perfect for form-fitting jackets and jeans that mellow with time.

- For classic jean longevity, the 14.25oz True Indigo is a top recommendation.

- Sustainable variants such as recycled cotton combined with indigo blends enhance eco-friendliness.

At Core Fabrics, our collection includes a variety of options to suit your needs. Spanning from raw finishes to sanforized treatments, each selection is designed for superior quality and value.

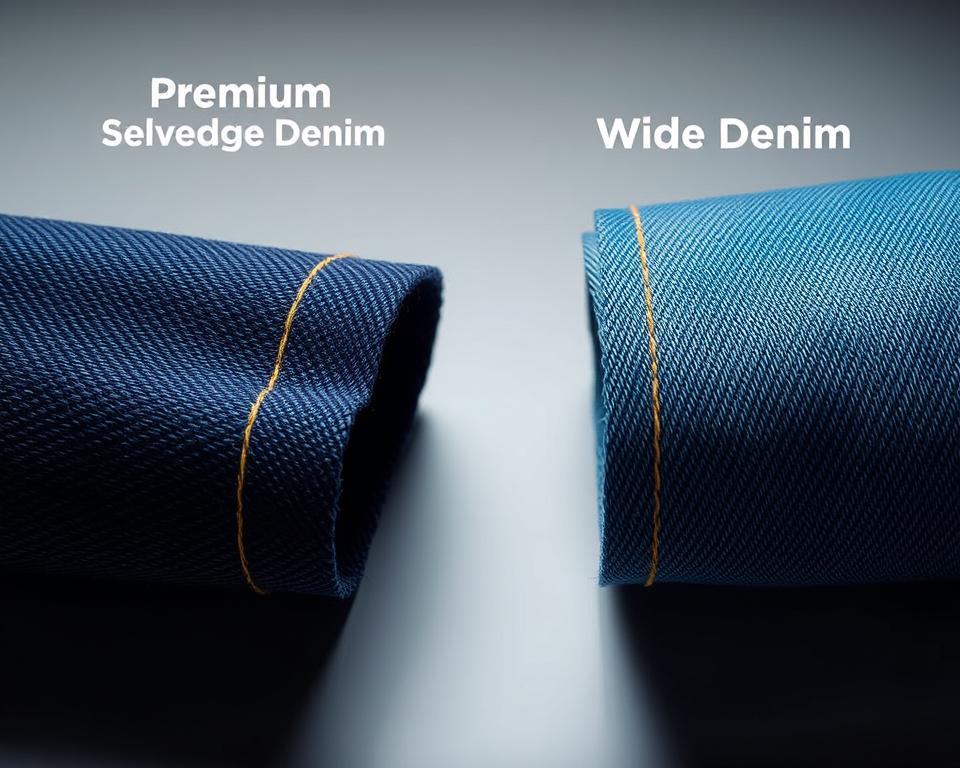

Comparing Selvedge and Wide Denim

In the creation of long-lasting and trendy pieces, the decision of material matters significantly. Among the prevalent selections are selvedge and wide denim, both offering different features. Understanding their differences can help you choose the right one for your endeavor.

Distinct Weaving Methods

Selvedge denim is woven on classic shuttle looms, yielding limited spans of 30-35 inches. This striped selvedge denim fabric method creates secure finishes, often featuring a signature red line. In contrast, wide denim is produced using modern projectile looms, resulting in widths of 60 inches or more.

Old-style shuttle looms yield roughly 3m per minute, while modern projectile looms reach speeds of 30 meters per minute. The variance in production speed affects both the cost and the surface quality of the outcome.

Advantages and Disadvantages

Selvedge denim is known for its premium quality and durability. Its narrow width suits it well for applications where defined edges and detail work are sought. However, it can be costlier, typically around $23 per meter.

Wide denim is budget-friendly, ranging at $8 per half-meter. Its broader span reduces waste, making it suitable for large projects like upholstery. However, it lacks the unique edge finish of selvedge.

| Attribute | Selvedge Denim | Wide Denim |

|---|---|---|

| Measurement | 30-35 inches | 60+ inches |

| Technique | Classic Shuttle Loom | Contemporary Projectile Loom |

| Output | 3m/min | 30 meters per minute |

| Cost | $23 per meter | $8 per half-meter |

When precise, structured edges are required—as in Grainline Thayer jackets—selvedge wins out. In contrast, wide denim provides cost-effectiveness and speedy production. Weigh your requirements carefully to decide.

Working with Selvedge Denim

Utilizing superior fabrics can transform your sewing endeavors. Whether you’re crafting trousers, outerwear, or frocks, grasping fabric quantities, proper sewing methods, and maintenance guarantees a polished result. We will examine ways to best utilize this classic textile.

Material Requirements for Jeans and Jackets

When planning your project, calculating the right amount of material is crucial. Men’s jeans typically require roughly 3-3.3 yards, factoring in flaws and potential shrinkage. Trucker-style jackets generally demand about 3.3 yards, while a skirt often needs 2 yards.

Creative pattern placement can help manage imperfections in the material. Embrace the natural defects by weaving them into your creative design.

| Item | Fabric Needed |

|---|---|

| Men’s Jeans | 3-3.3 yards |

| Trucker-Style Jacket | 3.3 yards |

| Dress | 2 yards |

Tips for Sewing and Care

Using the right tools and techniques ensures a polished result. Opt for #70–110 needle sizes and presser foot attachments suitable for thick fabrics. For contrast stitching, Gütermann rPET thread is a reliable choice.

Here are some additional tips:

- Use a tailor’s clapper for sharp creases without shine.

- Core Fabrics’ denim kits include topstitch thread, rivets, and 9mm jeans buttons for a professional finish.

- For structured edges, like those in jackets, selvedge is the preferred choice.

Proper care extends the life of your creations. Use minimal washing and opt for air drying to preserve fabric quality. Following these guidelines guarantees enduring results.

To Conclude

Using superior fabrics goes beyond mere durability—it’s about instilling personality. Selvedge denim exemplifies this principle, blending craftsman allure with enduring excellence. Whether you’re sewing jeans or a structured jacket, this material tells a story with every stitch.

With Core Fabrics, unleashing your creative potential is effortless. Experience our swatch service to gauge texture and weight prior to purchase. Furthermore, take advantage of free shipping for orders above $150 USD in North America.

Eco-friendly mixtures and classic washes are paving the way for the next generation of cotton fabrics. These trends offer new ways to add sustainability and style to your wardrobe.

Prepared to immerse yourself in superior fabrics? Shop now and discover the value of crafting with purpose. Your future project might just be that lasting masterpiece.